Industry Visit

Date: 24 September 2017

Company: Advance Valves, 142 A & B, Noida Special Economic Zone, NOIDA - 201305, INDIA

Total no of students:20 Faculty / Staff: Ms Gargi, AINST The student members of AEE-Delhi Chapter went for an Industrial Visit to Advance Valves, Noida. The visit was aimed to provide the students with an insight in the Valves Manufacturing Industry, and various challenges and opportunities it provides. The proceedings of the visit are as follows.

Mr.Rohit, gave an introduction to Valves Industry and role of Advance Valves, opportunities for freshers in Mechanical Engineering and other related disciplines in this field, business Philosophy, brief discussion on Valves, their types & controlling flow through a Valve, materials selection and how should an engineering student strengthen his/her salability

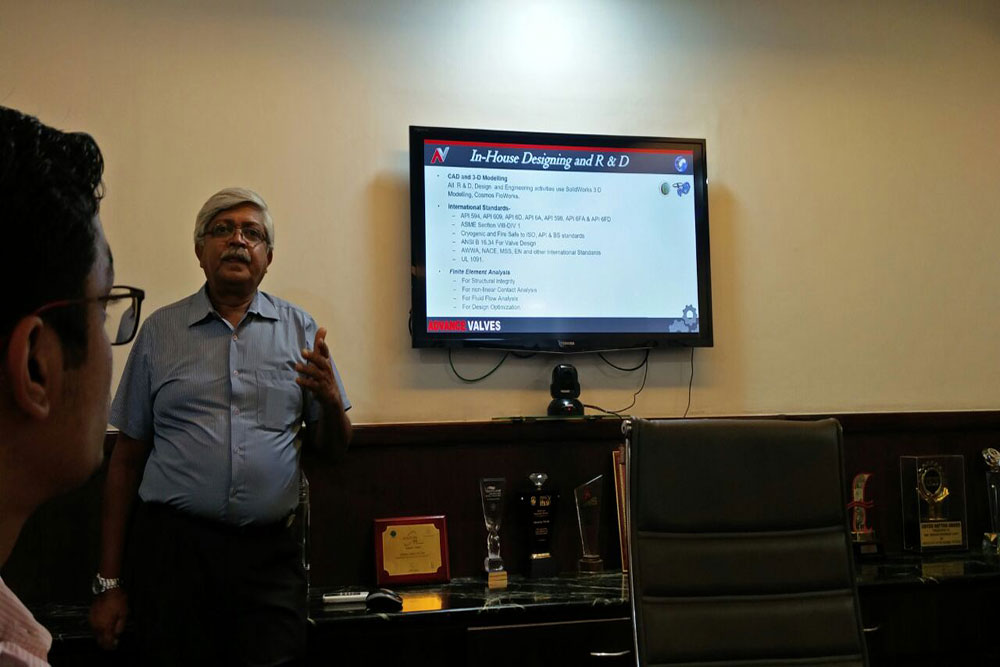

Mr.PriyankGarg, joint MD, Advance Valves interacted with the student visitors and discussed about Valves, role of mechanical engineers in various fields, 3-D modelling, various industry standards, CFD , finite element analysis, opportunities for freshers in Valves Industry and the importance of all round development.

Mr.Rajan Kumar, R&D, Advance Valves, showed us various types of valves and their components, gave a factory tour and showed various workshops like Conventional & PLC machine, area for check valves, robotic welding, testing area (like stress, hydro and gas testing), casting, surface handling (paintshop). Gave us an idea of the lead time while manufacturing and the total production capacity.

Conclusion The industrial visit to Advance Valves provided a great learning experience to all the students and helped them understand the actual working and manufacturing of valves and the various skills required to develop to have better job opportunities

At entrance of Advance Valves

At entrance of Advance Valves

Mr.Rohit discussing about valves

Mr.Rohit discussing about valves

Students attending the orientation session

Students attending the orientation session

Date: 10/08/2017

Company: Advance Valves, 142 A & B, Noida Special Economic Zone, NOIDA - 201305, INDIA

AEE Amity Chapter organized an industry visit to “Indosolar Ltd.” on 10th August, 2017 for its members, students of Amity Institute of Technology (AIT), AINST and ASET.

Indosolar ltd is a leading Indian manufacturer for photovoltaic cells. The company manufactures poly-crystalline solar photo-voltaic(SPV) cells from silicon wafers utilizing crystalline silicon SPV cell technology for converting sunlight directly into electricity through a process known as the photo-voltaic effect. The company is having its manufacturing unit located at Greater Noida, Uttar Pradesh, India.

The visit was aimed to provide a platform for the students and know the opportunities in Energy sector where they can get employed as energy professional and to know recent developments and future prospects in Renewable Energy sector.

Association of Energy Engineers (AEE) is a not for profit International Organization that enables collaboration, knowledge sharing, skill development in energy management engineering disciplines. Its vision is to be the essential resource for energy engineers and other technical professionals throughout the world for solutions that benefit humankind.

At the end of the visit students had a little talk with Dr. D. N. Singh, CTO, Indosolar Ltd. He thanked all the children for putting effort to learn about the solar energy systems and may take this field as their core in future. It was further followed by a small photo session with Dr.D.N.Singh with all the members of AEE Amity Chapter.

Students with the Technical Head at the production facility with all the required measures considered at the facility

Students with the Technical Head at the production facility with all the required measures considered at the facility

Dr. D.N. Singh, CTO, Indosolar Ltd. , With students of AEE Amity Chapter at the production Facility of Indosolar Ltd., Greater Noida, UP

Dr. D.N. Singh, CTO, Indosolar Ltd. , With students of AEE Amity Chapter at the production Facility of Indosolar Ltd., Greater Noida, UP

Date: 04/09/2019

Company: Air force Museum, Palam, New Delhi.

Total no of students: 15 students of 5th semester of B. Tech. (ANE), Batch 2017-2021.

Faculty / Staff: Dr. RS Tarnacha, Mr. Harish, S. and Ms. Neha Sharma

The Air Force Museum houses many aircrafts, aeroengines, weapon systems and mementos of historical achievements with brief details for each.

During the conduct of tour through the premises of the Museum, Dr. RS Tarnacha explained to the students the salient design features of the aircrafts, aeroengines and weapon systems on display. In all, the Museum hanger houses 15 different types of military aircraft that have formed the backbone of Indian Air Force since its inception on 8th October 1932. Some of the important aircraft are:

- The biplane aircraft Wapiti, Westland Lysander, the first plane to fly through the Khyber Pass in 1929.

- Hawker Hurricane, Hawker Tempest and Vickers Spitfire of World War II fame.

- The French Toofani (Ouragon) and Mystere fighters, the British Vampire, the first jet acquisitions of the IAF, the valiant Gnat fighter aircraft and Hawker Hunter.

- B-24 Liberator, Martin B-57 Canberra - the bombers, MI-4 Helicopter, the Marut (HF-24) - first fighter aircraft manufactured by HAL, the US made Sikorsky S-55 Helicopter, Fighters SU-7, Mig-21, MiG-23MF and reconnaissance aircraft MiG-25R.

- Transport aircraft, DC- Dakota, Packet, and TU-124.

- Basic Trainer aircraft, HT-32, designed and manufactured by HAL and Polish Iskra jet trainer.

- Piston engines of V-type and radial type and jet engines having centrifugal and axial compressors.

- ’OHKA', a Japanese Kamikaze Glider capsule of World War II.

The Museum has displayed photographs, models, trophies and items depicting the history of IAF from its establishment in 1932 onward, including T-59 tanks and a few remnants of the Pakistani Sabre aircraft destroyed by Indian pilots during 1965 conflict and KH-29 L, the armour-piercing, semi active laser guided, air to surface.

The students were taken inside the Dakota aircraft. The inner structural details of cargo compartment and instruments and controls in the cockpit were explained to them.

Conclusion: The visit was very illuminating, inspiring and educative experience for all the students giving them insight into design and development of different aircraft.

Comments of students:

The Spitfire Aircraft was the most interesting aircraft - Ravi Sharma

We saw various aircrafts for the first time – Shiva Sharma

It was a unique experience for me to see the MIG -23 having the variable sweep wing, offset canopy of Canberra bomber, the pictures of heroes in Air Force, their medals, achievements, uniforms etc. Overall experience was amazing. I learned a lot from the visit – Sourav Pehlawat

Orpheus turbojet engine of Gnat aircraft is one of the most overhauled engines in HAL. - Dipesh V Panchal

It was learning beyond textbooks which got us to appreciate the science and technology behind these flying wonders. We learnt the working of different type of aircraft engines like radial engines, V-type engines, engines with centrifugal compressors and axial compressors; which was very fascinating. - Parush Bamrah

Date: 17 January, 2019

Time: 12:30PM - 2PM

Students along with faculty members visited Honda Cars India Limited plant at Greater Noida. The visit started at 12:30 PM on Thursday, 17 January 2019 and ended at 02:00 PM the same day.

Mr. Sumit Kapoor, Chief HR Manager of Honda Cars plant, himself received us at the reception. We were then shown the Doors Assembly, Spot Welding, Vehicle Assembly and Vehicle Quality shop floors of Honda plant.

The students saw the robotic spot welding of BIW and robotic gluing of wind screen. On one station there were about 12 to 14 robots doing spot welding simultaneously. There were a number of automatic conveyors moving sub-assemblies from one point to another. The plant also practices Just in Time philosophy for its incoming inventory.

Total welding time for each vehicle is about 4 hours and the total assembly time is 2 days. The plant has a capacity of 250 cars per day. However, they are currently assembling around 212 vehicles per day. They currently manufacture only the Honda City model, but we were informed that in another 10 days, they will also start assembling the Honda Civic model. Total staff is around 2000 comprising of 900 permanent workers, 500 white collar employees and remaining temporary workers.

At the end of the visit to shop floor, Mr. Sumit Kapoor showed us a video on Honda Car plant and we were offered snacks and tea.

All the students and faculty members were very impressed with the visit. There was a lot to learn for the students.

Date: 17th October, 2018

Time: 10:00 am to 4:00 pm

Amity Institute of Technology organised a one-day visit to Tata Motors, Lucknow, on October 17, 2018, for third year students of B.Tech. Automobile Engineering so as to give the students an exposure of Industrial practices and processes.

11 students who were accompanied by 4 faculty members visited the plant which caters the demand of heavy and mid segment commercial vehicles for Tata Motors’ product portfolio.

Students learnt about many technical aspects which are involved in making a vehicle perform on road. They were exposed to the working and structure of the organization through corporate presentation followed by visit to the following facilities:

- Training Division

- Assembly Line

- Trim Line sub- assembly

- Frame sub-assembly

- Paint shop

Student left the campus on 2018-10-16 by road, staying overnight at Lucknow and returned on the night of 2018-10-17 after the visit.

At Tata Motors, we were received by Ms. Jasneet Rakhra, DGM, HR, Tata Motors, Lucknow. She was also instrumental in organizing this visit for us. Some of the faculty members also met Mr. Kumar Lalit, GM (HR, ER and Admin). A brief presentation about Tata Motors was given by Ms. Jasneet. This was followed by a lecture on safety practices to be followed by us while visiting Tata Motors shop floors. After that the visit to above mentioned areas started.

Date: 27 January 2020

Time: 10:00 AM – 03:00 PM

Students of Batch 2018-2022 along with Mr. Manish Sharma (Tata Technologies) visited Tata motors plant at Pantnagar, Uttarakhand. The visit started at 10 AM on Monday, 27 January 2020 and completed at 3 PM the same day.

Mr. Brij Lal Arora, Chief HR Manager of Tata plant, himself received us at the reception. Total staff in the plant is around 5000+. A brief presentation and video on Tata motors journey was shown and a quick question answer session was also conducted. We were offered snacks and tea. We have seen the frame shop, TCF shop and the engine shop.

Frame Shop or BiW Shop: Students saw the robotic spot welding of the main frame. On one station there were 2 fully automatic spot-welding robots doing spot welding simultaneously. There were several automatic conveyors moving sub-assemblies from one point to another. The plant also practices Just in Time philosophy for its incoming inventory. Total welding time for each vehicle is about 1 hour.

TCF shop (Trim, chassis and final): In this plant there are 3 TCF shop. We went to TCF1.There were 22 workstations in which the final vehicle is rolled out. The plant has a capacity of 1650 vehicles per day. However, they are currently assembling around 180 vehicles in a shift in this TCF shop. The Shop was manufacturing of Tata Mega XL and Tata Ace model, but we were informed that the model Tata Intra was also being manufactured.

Engine shop: We have seen the assembling of 2 cylinder and 4-cylinder Diesel engines. After manufacturing of engine, every Engine is tested in Engine Test rig. The engine shop has 24 test rigs upon which engine is tested for performance parameters.

Students were very excited and enthusiastic to see the production of a vehicle and its various aspects. The students learnt the processes involved in manufacturing of a Frame, BiW. Also, it was a great experience to see the vehicle getting assembled at different workstations.

Date: 11th Feb 2020

Time: 12:00 PM to 4:00 PM

The students of BTech (AME), BTech (ANE) of batch 2018-22 and 2019-23 along with faculty members of Amity Institute of Technology have visited the AUTO EXPO 2020 on 11th Feb 2020. The Auto Expo is biennial automotive show held in Greater Noida. It is the Asia’s largest and the world’s second largest motor show. It is organized jointly by the Automotive Component Manufacturers Association (ACMA), Confederation of Indian Industry (CII), and society of Indian Automobile Manufacturers (SIAM).

The Auto Expo provides manufacturers with a platform to showcase current automobile models, debuts, concept cars and out of production classics and create awareness about their product and brand among industry representatives, dealers, auto journalist, car enthusiasts and the everyday buyer.

For the 15th edition of the Auto Expo the motto was “The future is electric”. Thus, there were many OEM’s this time to showcase their latest developments in the Electric Automobile sector.

We began with HAVAL GWM latest offering, the R1, which is a sub-compact e-vehicle and is autonomous. It uses a 28.5KWh battery, producing a power of 48 PS allowing it to have a maximum range of 300 kms. In a one-time charge of 40 mins the battery charges to 80%. Unlike the R1 which is yet to be launched, we also saw the ZS EV from Morris Garages (MG), which is another electric vehicle offering a maximum range of 340km in one charge which has been launched in the market.

From the indigenous manufacturer TATA, the Nexon EV- which is India’s first sub-4-meter compact electric SUV was showcased. It uses 30.2KWh battery and runs for 312 km in one charge and takes 60 min to charge 80%. Tata was also conducting a test drive session to showcase its ability at the expo. Also, from TATA was bus called the Starbus LNG, which is first of its kind -hybrid bus to be launched. In combination with hydrogen gas and oxygen, the bus produces electricity that powers the motor, with water and heat as a byproduct, thus, producing zero emissions. We appreciated the impact this vehicle would have in reducing carbon emissions once launched in the consumer market.

Also, from the commercial vehicle segment Mahindra showcased it’s Blazo, which was kept in benchmarked condition giving the details of the engine, transmission etc. which was in fact helpful for people to learn those mechanisms. It is also presented its Super XUV 300 rally car which won the INRC piloted by Mr. Gaurav Gill and Mr. Musa Sherif.

It was an excellent ice-breaking experience for all the students as they got to interact with industry professionals from different manufacturers as well as amongst themselves discussing the latest trends in the automobile industry.