RESEARCH CENTERS & LABS

High Performance Computing Machine

High Speed Camera

Compact Thermal Camera

Super-Compact DSLR Camera

Plasma Fabrication

Smart Materials & Structures Lab

Centre for Mechatronics

Non-Destructive Testing Lab

ME Lab Equipments-2024

|

SNo. |

Department |

Name of the lab and location |

Name of Equipment |

Specification |

Application |

|

1 |

Department of Mechanical Engineering |

Advance Materials Lab E1-LG 04 |

Electronic Weighing Balance |

Caliberated capacity 220g, Readability 0.1 mg |

To weight the less amount of mateials for the composition of reinforcement in the composite material |

|

2 |

Double Disc Polishing Machine |

Double Disc with range of 50-1500 rpm |

Used for the composite surface morphology and finishing |

||

|

3 |

Ball Milling machine |

zirconium balls, two containers of 500 gm capacity each. Mesh of 1-10 micron. Motar rpm 100. |

Used for mixing of different materilas and size reduction as well. |

||

|

4 |

Tubular Furnace |

Vaccum chamber with maximum capacity of 1500 deg centegrate |

Used to melt the materials for composite preperation without exposure of environmental contamination |

||

|

5 |

Stir Casting furnace setup |

Electric furnace controlled variable up to 1200 deg, Variable controlled stirrer up to 100 rpm |

Used for composite preperation by mixing the reinforcements in moltent stage of the matrix. |

||

|

6 |

Muffle Furnace |

Convective heating furnace with 1000 deg. |

Used for sintering of the compat composites. |

||

|

7 |

Hydraulic Press |

2 Ton variable applied load capacity. Working bed of 100mm X 100mm |

Used for the compaction of powdered material to prepare composite materials using powder metalergy |

||

|

8 |

Refrigeration and Airconditioning Lab E1 LG 04A |

Refrigeration Test Rig |

Reciprocating compressore, 230V-50Hz. Air cooled evaporator. automatic expansion valve. Refrigerant (R-134A) |

To explain the vapour compression refrigeration system |

|

|

9 |

Compressor Test Rig |

Double stage. |

To explain how the compressor works |

||

|

10 |

Air conditioning Test Rig |

Compressor 1 ton, Kirlosker maker, |

To explain theory of Air- Conditioning |

||

|

11 |

Vapour Absorption Refrigeration System |

Refringent no : |

To explain how the refrigeration take place by using low grade thermal energy |

||

|

12 |

Ice Plant Test Rig |

Compressor Model : |

To examine and learn ice formation process |

||

|

13 |

Automobile Air Conditioning Test Rig |

Used Battery: 12 volt |

To learn the Air Conditioning in Automobile |

||

|

14 |

Mechanical Engineering Workshop E1 LG 06-08 |

Power Hacksaw Machine |

1 HP 3 phase motor RPM-1440 |

Used to cut large sizes of metals in to any size. |

|

|

15 |

Arc Welding machine |

2 phase machine 220v |

Used for permanent joining of thick or thin metal pieces in any orientation without fillers. |

||

|

16 |

Gas welding set |

Oxygen & acetelene cylinder, mixing chamber with welding torch |

Used for permanent joining of thin metals with and without fillers. |

||

|

17 |

TIG Welding setup |

two phase machine 220v |

Used for the permanet joining of pipe-lines or shells using inert sheilding gas. |

||

|

18 |

Lathe Machines (3&4 Jaw chucks) |

Bed length 3’ |

Used for machining operations such as turning, facing knurling, boring threading |

||

|

19 |

Horizontal milling machine |

2HP 3 phase motor RPM-1440 |

Used for gear cutting and finishing. |

||

|

20 |

Shaper machine |

1.5 HP 3 phase motor |

Used for slot cutting v type u type in any orientation. |

||

|

21 |

Padestal Drilling machine |

1 HP 1 phase motor |

For small scale working on hole preperation |

||

|

22 |

Bench Grinder |

0.5 HP 3 phase motor, RPM-2800 |

Used tool finishing and sharpening. |

||

|

23 |

Open Hearth Furnace |

1'x1', 0.5 hp blower |

Used for recrystilization of metals and to heat up to semi-plastic stage for forging operation. |

||

|

24 |

Electric furnace |

three phase 440v |

Used of heat treatment and melt the metals for casting. |

||

|

25 |

Surface Grinder |

0.75 HP 3 phase motor |

Used of the smooth surface finish on metal specimen |

||

|

26 |

Radial Drill Machine |

BVR-3 with radial drill vice, 2 HP 3 phase motor |

Used for making holes of different diameters in the metal and non metal pieces |

||

|

27 |

Fluid Mechanics Lab Advance Fluid Machine Lab E1 LG 10 |

Venturimeter, Orificemeter & Rotameter test rig |

Centrifugal pump motor capacity-0.5 HP/Single phase AC 220 V/5-15 amp/50Hz |

Determine the value of Cd (coefficient of discharge) for venturimeter, Orificemeter and Rotameter |

|

|

28 |

Reynolds Apparatus |

Centrifugal pump motor capacity-0.5 HP/Single phase AC 220 V/5-15 amp/50Hz |

Determine the Reynolds number for the laminar ,transition and turbulent flow of liquid (water) and visualization the flow path with the help of Die(K2MNO4) |

||

|

29 |

Losses due to pipe Friction apparatus |

Centrifugal pump motor capacity-0.5 HP/Single phase AC 220 V/5-15 amp/50Hz |

Determine the friction coefficient (f) for each pipe for the flowing liquid water |

||

|

30 |

Discharge over notch apparatus |

Centrifugal pump motor capacity-0.5 HP/Single phase AC 220 V/5-15 amp/50Hz |

Used to determine the Cd for different notches |

||

|

31 |

Bernoulli’s theorem apparatus |

Centrifugal pump motor capacity-0.5 HP/Single phase AC 220 V/5-15 amp/50Hz |

Verify the Bernoulli’s theorem |

||

|

32 |

Meta centric height apparatus |

Tank size-55x50x40 cm3 |

Determine the meta centric height(GM) of the ship (boat) for different tilting position. |

||

|

33 |

Pitot tube apparatus |

Centrifugal pump motor capacity-0.5 HP/Single phase AC 220 V/5-15 amp/50Hz |

Determine the surface head loss(normal) |

||

|

34 |

Impact of jet on vanes |

Centrifugal pump motor capacity-0.5 HP/Single phase AC 220 V/5-15amp/50Hz |

Determine the COI (coefficient of impact) for both vanes |

||

|

35 |

Centrifugal pump test rig |

Electric supply-3 phase AC 415 V/5Hz |

Determine the hydraulic efficiency of centrifugal pump |

||

|

36 |

Pelton wheel turbine test rig |

Supply pump set- centrifugal pump-3 phase AC 415 V/50Hz |

Determine the hydraulic efficiency of Pelton wheel turbine |

||

|

37 |

Francis turbine test rig |

Supply pump set- centrifugal pump-3 phase AC 415 V/50Hz/7.5 HP |

Used to determine the hydraulic efficiency of Francis Turbine |

||

|

38 |

Kaplan turbine test rig |

Supply pump set- centrifugal pump-3 phase AC 415 V/50Hz/7.5 HP |

Determine the hydraulic efficiency of Kaplan Turbine |

||

|

39 |

Internal Conbustion Engine Lab E1 LG 09 |

Four stroke 3 cylinder petrol engine test rig |

Number of cylinder-3, Number of stroke-4 |

Determine the BHP, Brake thermal efficiency, IHP , Mechanical efficiency BSFC. |

|

|

40 |

4stroke single cylinder (VCR) engine test rig |

Number of cylinder-1, number of stroke-4 |

Determine the BHP, Brake thermal efficiency, IHP , Mechanical efficiency BSFC. |

||

|

41 |

Mechanics of Materials Lab E2 LG 02A |

Impact Testing Machine |

IZOD 170 J and CHARPY 300 J test |

Used to calculate toughness of material using strain energy strored up to fracture. |

|

|

42 |

Spring Testing Machine |

SINGLE PHASE 220 V AC ELECTRIC SUPPLY/5 AMP/50HZ Tensile and Compression Test (Helical spring). |

Used to accurate testing of spring stiffness |

||

|

43 |

Hardness Testing Machines |

Rockwell and Brinell Hardness Test Capacity: 187.5 Kg |

Used to calculate hardness of any type of surface of materials |

||

|

44 |

Universal Testing Machine |

Capacity: 20 ton loading. Hydraullic |

Used to check tensile, bend and compressive strength |

||

|

45 |

Fatigue testing machine |

SINGLE PHASE 220 V AC ELECTRIC SUPPLY/5 AMP/50HZ |

Used to test the ultimate strength of the materials on cyclic loadings |

||

|

46 |

Torsion Testing Machine |

SINGLE PHASE 220 V AC ELECTRIC SUPPLY/5 AMP/50HZ Capacity: 50 Kgm |

Used to test the ultimate strength of the materials on twisting. |

||

|

47 |

Mechatronics Lab Research Lab E1 G08A |

Hydraulic Trainer Kit with power pack |

4/2, 4/3 solinoid valve, Direct acting pressure releif valve, 2 way flow control valve, double acting cylinder range 0.19 cm, 3 phase, 2 HP, 1440 rpm, 415 V motor |

Used to design working hydraulic pressure pipeline circuits for various output works. |

|

|

48 |

Pneumatic and Electrical Trainer Kit (P1 + EP1) |

FRL unit, single acting and double acting cylinders, solinoid and control valves. |

Used to design working pneumatic pressure pipeline circuits for various output works. |

||

|

49 |

Ni Myrio Mechatronics kit,Ni starter kit & Ni Embedded kit |

Softwares and activation cards with high performance computing facilities. |

Used for simulations of different Mechatronic systems |

||

|

50 |

CAM and Automation Lab E1 G07 |

3D Printer |

Model Cubex (USA) Printing technology FFF (Fused Filament Fabrication) Printing area 150× 150× 200 mm No's of Nozzle 3 |

Used to print an object as 3D CAD imgaes |

|

|

51 |

CNC Milling Machine |

Model MT-250 |

Used for milling operations with maximum accuracy in ductile metals and non metals based on NC part programming |

||

|

52 |

Heat & Mass Transfer Lab E1 G09 |

Shell and heat exchanger |

Electricity supply-single phase AC 220 V/5-15amp/50Hz |

Used to describe theory of Heat & Mass Transfer |

|

|

53 |

Parallel and counter flow in a double pipe heat exchanger |

Electricity supply-single phase AC 220 V/5-15amp/50Hz |

Used to describe theory of Heat & Mass Transfer |

||

|

54 |

Thermal conductivity of metal rod |

Electricity supply-single phase AC 220 V/5-15amp/50Hz |

Used to describe theory of Heat & Mass Transfer |

||

|

55 |

Thermal conductivity of insulating powder |

Electricity supply-single phase AC 220 V/5-15amp/50Hz |

Used to describe theory of Heat & Mass Transfer |

||

|

56 |

Thermal conductivity of liquid |

Electricity supply-single phase AC 220 V/5-15amp/50Hz |

Used to describe theory of Heat & Mass Transfer |

||

|

57 |

Force convection Apparatus |

Electricity supply-single phase AC 220 V/5-15amp/50Hz |

Used to describe theory of Heat & Mass Transfer |

||

|

58 |

Pin fin in natural Forced convection apparatus |

Electricity supply-single phase AC 220 V/5-15amp/50Hz |

Used to describe theory of Heat & Mass Transfer |

||

|

59 |

Conduction through composite wall |

Electricity supply-single phase AC 220 V/5-15amp/50Hz |

Used to describe theory of Heat & Mass Transfer |

||

|

60 |

Emissivity measurement Apparatus |

Electricity supply-single phase AC 220 V/5-15amp/50Hz |

Used to describe theory of Heat & Mass Transfer |

||

|

61 |

Stefan Boltzmann Apparatus |

Electricity supply-single phase AC 220 V/5-15amp/50Hz |

Used to describe theory of Heat & Mass Transfer |

||

|

62 |

Forced/ natural convection Apparatus |

Electricity supply-single phase AC 220 V/5-15amp/50Hz |

Used to describe theory of Heat & Mass Transfer |

||

|

63 |

Drop and film condensation Apparatus |

Electricity supply-single phase AC 220 V/5-15amp/50Hz |

Used to describe theory of Heat & Mass Transfer |

||

|

64 |

Non Destructive Testing Lab E3 LG 17 |

Ultrasonic Flaw Detection testing machine. |

Range: 0 to 9999 mm of steel velocity. |

Used to observe any crack inside the materials without destroying the same using ultrasonic velocity |

|

|

65 |

Magnetic Particle |

Equipment model -VT– MPT-PS 1500-A. |

Used to find out any cracks inside the materials without destroying the same using effect of magnetic fields |

||

|

66 |

Concrete Tester machine |

Model – UX4600. |

Used to observe any crack inside the concrete without destroying the same |

||

|

67 |

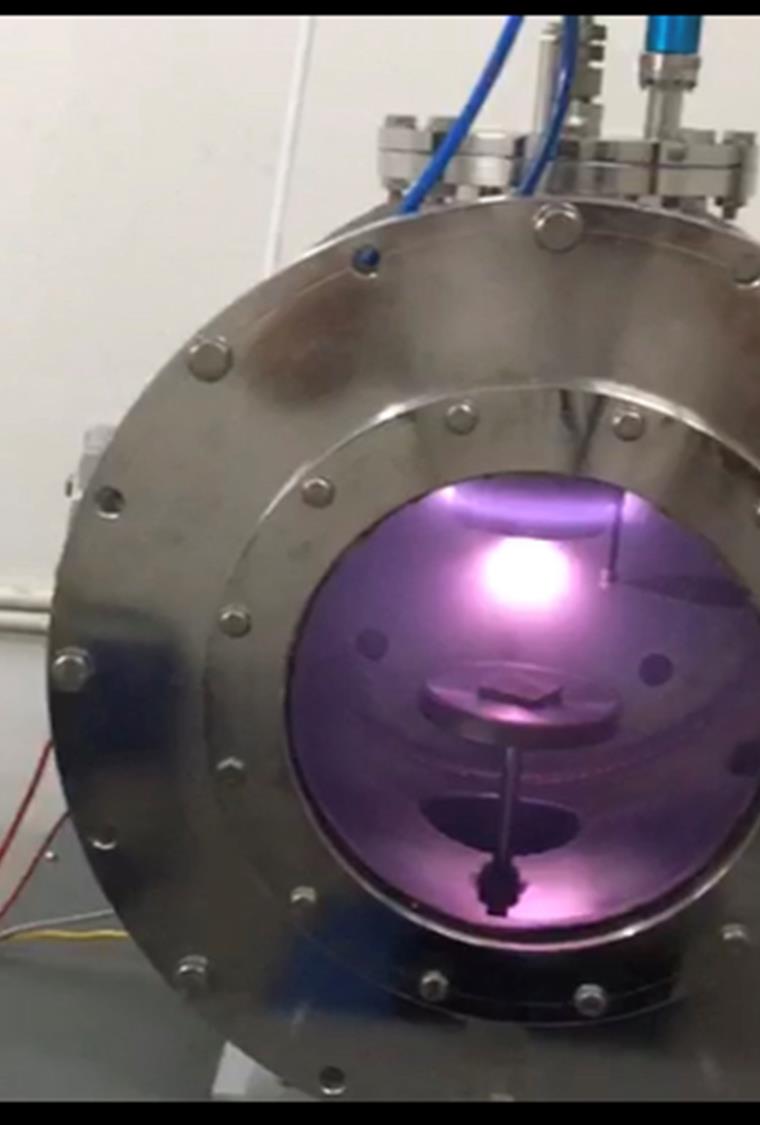

Plasma Lab E1 G08 |

Plasma Etching, functionalization, and coating (any conductive material) |

Vacuum Chamber Material: SS304 |

Research |

|

|

68 |

CFD Lab E1 G05 |

Temperature and flow visualization of the engineering systems |

Phantom v341 |

Research |