India Coordinator and PI -DR. Nutan Kaushik, Director General, Amity Food and Agriculture Foundation, Amity University, Noida

nkaushik5@amity.edu

Bringing Techno solutions for valorisation of seafood industry waste

Problem:

Rapid growth of fish processing has resulted in increasing quantities of waste. It is estimated that fish processing waste after filleting accounts for approximately 75% of the total fish weight. Global fish waste is estimated to be approximately 100 mMT, and more than 4 mMT in India. These wastes are dumped, buried, used for landfilling, or incinerated, increasing environmental hazards, pollution, and threat to public health and increasing greenhouse gas emissions.

These wastes are inexpensive sources of amino acids and protein, underlining their potential to be used as animal feed and fertilizer. When compared with chicken, trout fish has 19 times more omega-3 fatty acid, oysters and mussels are 76 times richer in vitamin B-12 and have five times more iron and carp is nine times more calcium-rich, according to the researchers.

Social problem addressed

Seafood waste disposal is a huge problem as they are highly amiable to microbial degradation unless processed properly. If not handled properly it results in pollution and health crisis among inhabitants of communities. These by-products are a potential source for various active ingredients and biomolecules such as omega -3, vitamins and protein etc. Along with providing effective and economical solution, utilization of seafood waste will also enable to tackle another critical problem of malnutrition

India has the lowest average protein consumption (at 47 gm per person per day) as compared to other Asian countries as well as developed nations. As per research, more than 73% of India is protein deficient. One of the main causes of deficiency is the lack of awareness among people about the importance of proteins in the body. Among adults, 36 percent of women have a BMI below 18.5, indicating a high prevalence of nutritional deficiency. Among women who are thin, almost half (45 percent) are moderately or severely thin. Underweight is most common among the poor, the rural population, adults who have no education and scheduled castes and scheduled tribes. Seafood by-products can be utilized to address issues of malnutrition.

Bringing changes in the community

We aimed to provide effective solutions towards development of value-added products from seafood waste. In order to achieve this project plan was devised to study and suggest necessary improvements in seafood by-product utilization value chain.

This project aimed to provide a sustainable solution to critical issue of waste disposal along with malnutrition. It will contribute towards development of a comparatively cleaner, more efficient, and healthy society.

Solution one

Removal of soluble protein from meat and seafood industry wash water and utilization of precipitated protein

Production of surimi from fish is a water-intensive process. In this process, fish mince is repeatedly washed with chilled water to remove sarcoplasmic protein and concentrate myofibrillar protein. Apart from the generation of solid waste like head and viscera, skin, and bones, etc the process also produces a large amount of wash water as waste.

Due to the escalating drive for the consumption of non-meat protein production of surimi has increased significantly over years. In the year 2018 global surimi production was about 211 MT FAO, 2018 . According to our survey with the surimi industry, approximately 300-kilo liters of wash water are produced per day for the production of 250 MT of surimi. Due to the presence of high content of soluble protein 1.42 mg/ml / nitrogen content, around 200 ppm in the generated wash water which is 20 times higher than the maximum limits set by CPHEEO, the wash water cannot be discharged into the sea or reused.

The conventional practice of treating wash water includes ETP treatment which is inefficient in reducing nitrogen content of wash water or they are not environmentally sustainable. Discarding the soluble protein-rich water into streams incurs high disposal costs, leads to a highly negative impact on the environment, and causes the loss of valuable components. Consequently, the surimi industry faces environmental and economic challenges in reusing and discarding this wash water.

We have optimized a green technology for the removal of soluble protein from surimi industry wash water using isoelectric precipitation. The process gave a positive result by reducing the nitrogen content of the wash water from 200 ppm to less than 50 ppm by removal of up to more than 85 of soluble sarcoplasmic protein bringing it down to safe limits. The precipitated protein can be used for various purposes.

Solution 2

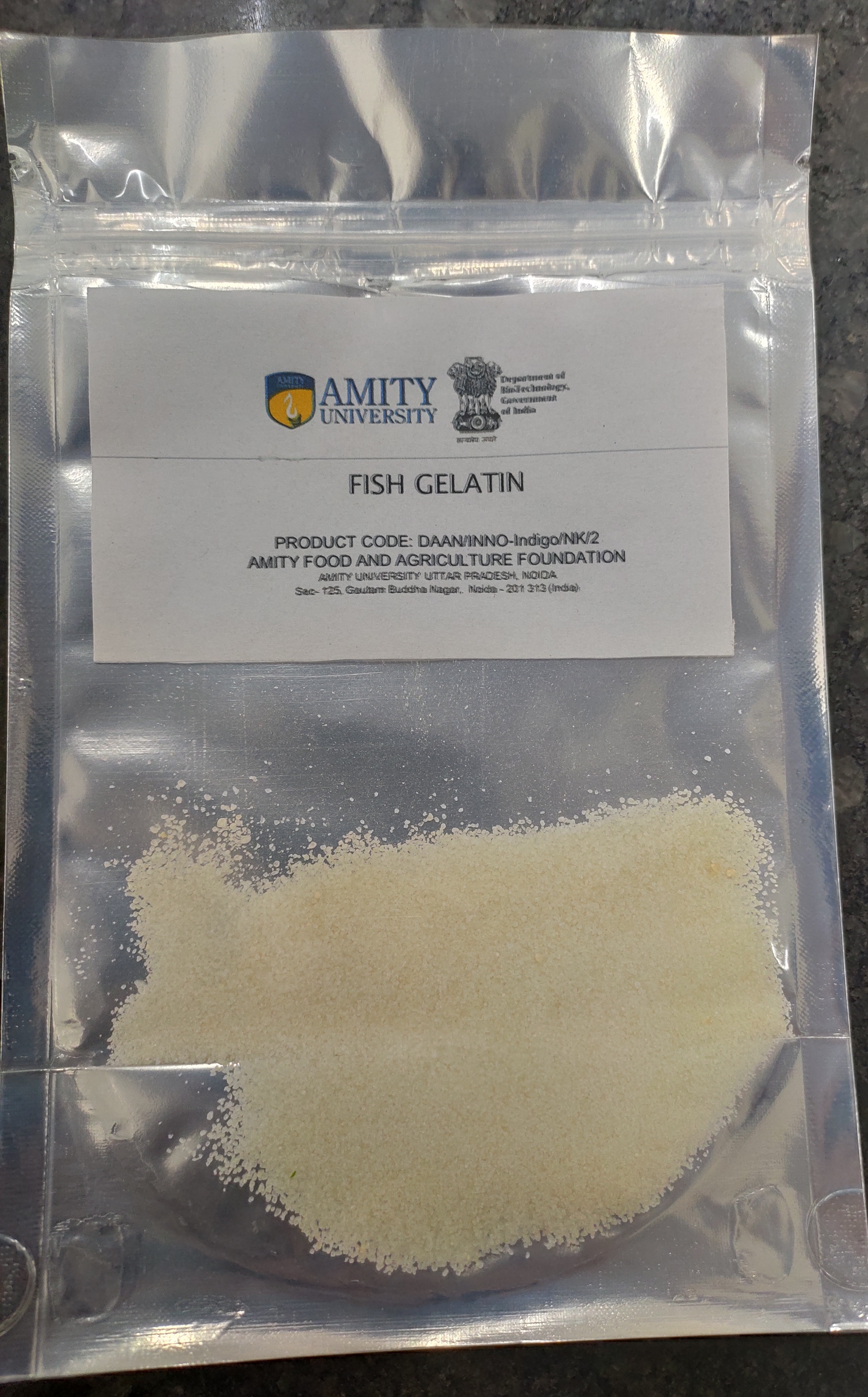

Production of gelatin from fish skin and bones having various functional properties

The utilization of waste from fish processing industry for production of value-added products has attracted substantial attention. We have developed a method to produce gelatin from fish skin and bones. In our study we have extracted Gelatin from industrial sample of Pink Perch skin and bones, and further, optimized of gelatin extraction process by Response Surface Methodology (RSM) to maximize yield along with high quality. ph of the treatment solution The process indicated a potential for gelatin production from industrial waste.

Solution 3

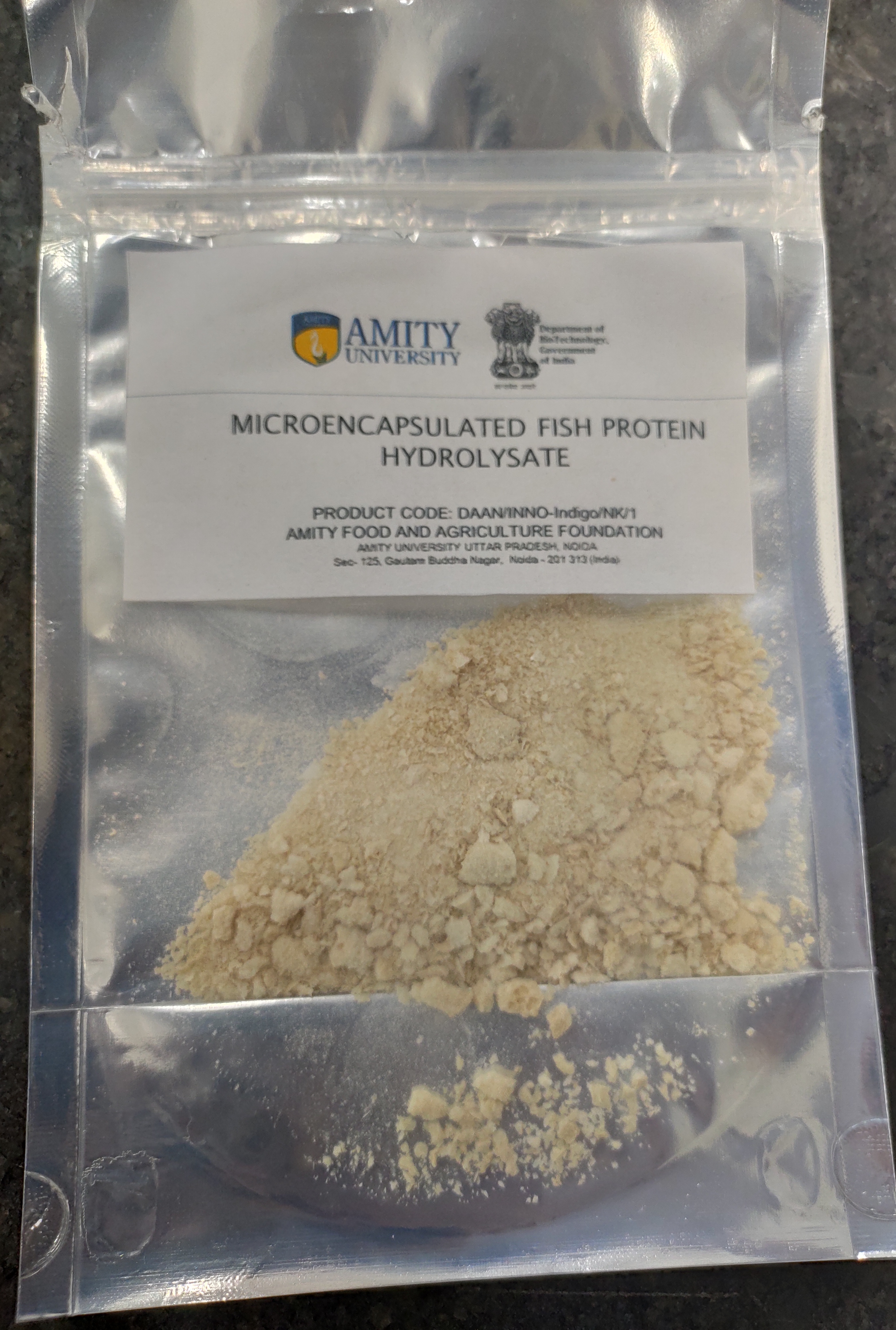

Production of Protein Rich microencapsulated hydrolysates from Fish and Fish by products

Protein deficiency is a serious problem in India. Fish head and viscera, a waste from fish processing industry, is rich source in protein however currently not being used for high value protein. We did the screening of enzymes to select suitable enzyme for enzymatic hydrolysis. In this study two commercially available enzymes i.e Alcalase (A) and Trypsin (T), one mixture of two enzymes Bromelain plus Papain (BP), and Endogenous (E) enzymes were used for enzymatic hydrolyses. Protein enriched protein hydrolysate containing 85 % protein was produced from head and viscera which can be used as protein supplement or can be added in different food preparation. Ready to cook protein enriched soup has been prepared using this hydrolysate. Very much suitable for malnourished population.