Technology and Process Developed

PROCESS EXTRACTION OF GELATIN FROM FISH SKIN AND BONES

Rapid growth of fish processing has resulted in increasing quantities of waste. It is estimated that fish processing waste for approximately 75% of the total fish weight. Global fish waste is estimated to be approximately 100 mMT, and more than 4 mMT in India. These wastes are environmental hazards and threat to public health and increasing greenhouse gas emissions. These wastes are inexpensive sources of amino acids underlining their potential to be used as animal feed and fertilizer. These fish industry by-products are rich source of commercially valuable biomolecules such as proteins, gelatin, omega-3 polyunsaturated fatty acids, vitamins (A, D, E, K), enzymes, bioactive peptides, amino acids etc. and therefore have high potential to be used as high-value products such as gelatin. The typical gelatin extraction method includes more than two steps which makes the process time-consuming and cost-intensive.

During this project a technology has been developed for extracting gelatin from skin and bones obtained from surimi industry using rapid and green extraction technology. Developed technology uses single step extraction method which minimizes time and resources utilized during extraction. Developed technology also utilizes combined biomass of skin and bones which is conventionally discarded due to operational difficulty in processing. Extracted gelatin had high yield and gel strength. It also had good techno-functional properties gelatin properties which suggested its potential application in food product development. Extracted gelatin also exhibited moderate anti-oxidant activity. The process developed utilizes by-product thus reducing the cost of raw-material. It is a simple process and provide ease of operation

Fish Gelatin

Low-fat Ready to Cook Chicken meatballs from Fish Industry By-Products

In developing countries like India, especially during the last decade, paradigm shift in lifestyle has led to increased consumption of convenience ready to cook meat products. Comminuted meat products contain approximately 20–30% fat, therefore, it is essential for the meat industry to reduce the fat contents of their products. In meat products, fat contributes to the flavor, texture, mouthfeel and overall sensation of lubricity of the product. Fat reduction can, therefore, significantly affect the acceptability of a product and increase the toughness of meat products. However, consumption of fat rich food products is associated with health risk such as obesity, and cardiovascular disorders. In this project low-fat ready to cook (RTC) chicken meatballs were developed using gelatin extracted from fish industry by-products. The product aimed to reducing the fat content of chicken meatballs while maintain its textural and sensory properties.

The low-fat RTC meatballs had 50% lower fat content in comparison to the commercial meatballs. Addition of gelatin has significantly improved the cooking, textural and functional properties of RTC meatball. Low-fat RTC meatballs has the higher consumer acceptability as compared to commercial sample.

Low-Fat Ready to Cook Chicken Meatballs

Process for removal of soluble protein from meat and seafood industry wash water and utilization of precipitated protein

Production and subsequent processing of large amount of food grade meat and seafood products generates huge quantity of by-products. Apart from solid rest raw material like head and viscera, skin and bones etc this industry also produces a large amount of wash water with high concentration of soluble proteins (>227 ppm). Discarding of this wash water poses serious biological threats, high disposal cost and loss of valuable components.

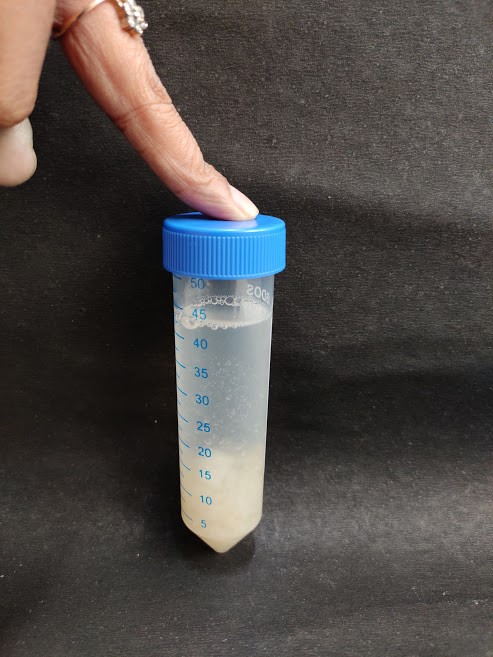

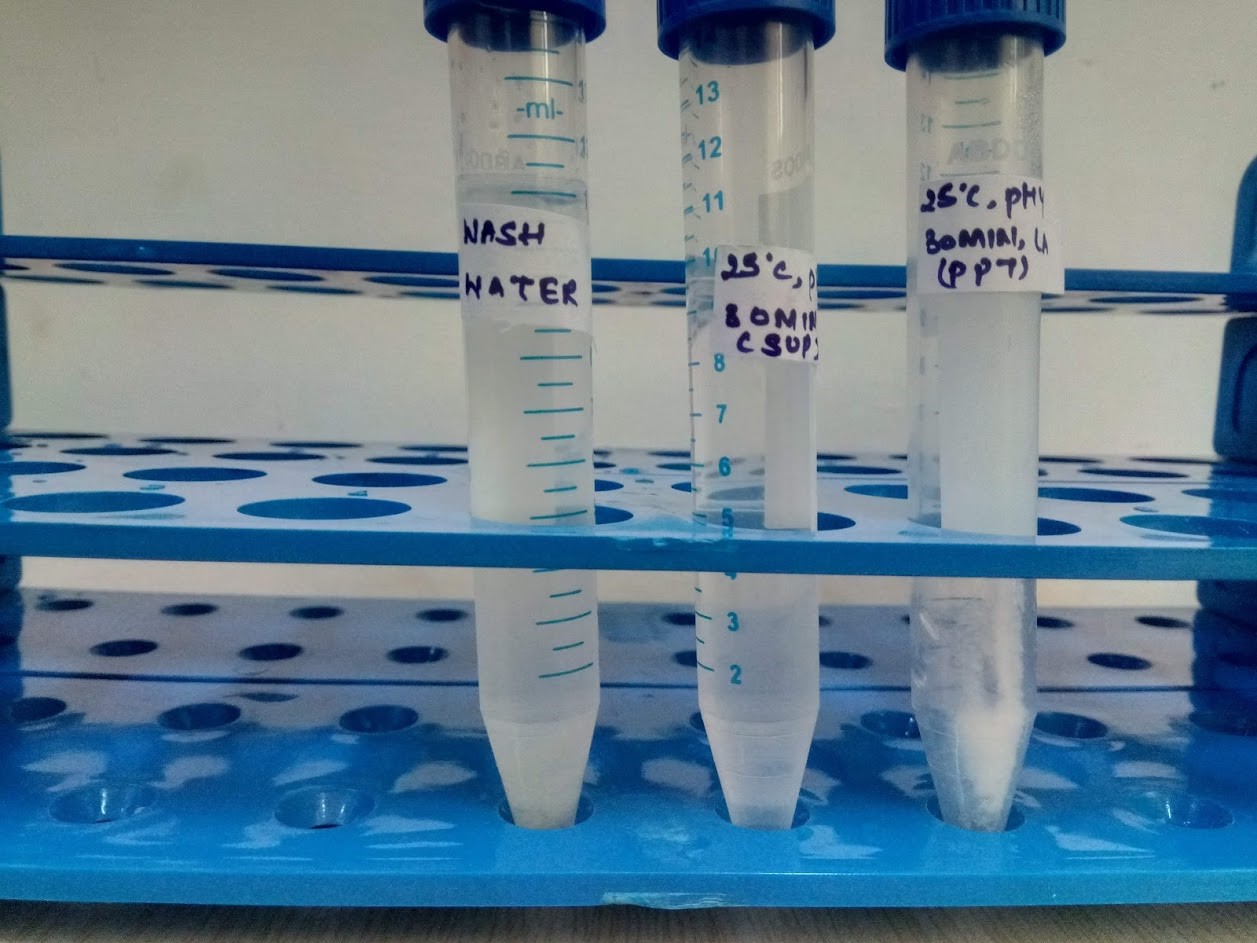

During this project a rapid process for removal of soluble protein from meat and seafood industry wash water using isoelectric precipitation has been deveoped. Developed process utilizes organic acid at room temperature which makes the process cost-effective and environmentally sustainable. Developed process is highly efficient as it removes upto more than 85% of soluble protein (<18 ppm).

Treated Wash Water

A Process for Utilization of Fish Industry By-Products as Protein Hyrolysate and Development of Ready to Cook Soup Mixes (Patent Application no: 202211019553)

Major population of India is suffering from protein deficiency. Malnutrition remains a silent emergency in India, where more than half of all children under the age of four are malnourished, 30 percent of new-borns are significantly underweight, and 60 percent of women are anaemic. Malnutrition costs India at least $10 billion annually in terms of lost productivity, illness, and death and is seriously retarding improvements in human development and further reduction of childhood mortality.

Fish by-products serves as an excellent alternative to current protein sources owing to its high protein content and well-balanced amino acid profile including essential amino acid which enables widespread application for production of dietary supplements, nutraceuticals, functional food, and food fortification. The fish industry and fish market generate a total of 100 mMT of by-product worldwide and more than 4 mMT in India. Currently, these by-products are dumped back in sea which causes high impact on the environment and public health due to the release of organic and inorganic compounds and loss of valuable component such as protein and omega 3 fatty acids. The proper fish by-products management aids in eliminating harmful effects on environment and on other hand industry can also earn extra profit by producing value added products with the help of new technologies. Therefore, utilization of these by-products in formulation of ready to cook soup mixes would aid in an economical and ecologically sustainable utilization.

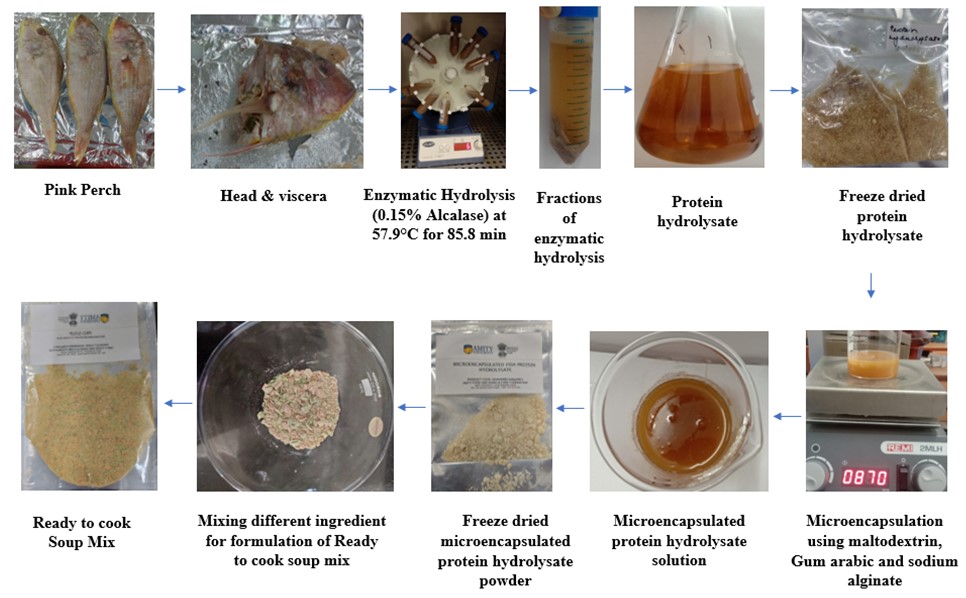

Amity has worked on production of protein hydrolysates from Pink Perch head & viscera obtained from surimi industry through enzymatic hydrolysis technique. Fish protein hydrolysate contain high amount of essential acids and exhibit a wide range of functional properties which include high solubility and good emulsification capacity, foaming ability, oil and water holding capacity. Then microencapsulation of the protein hydrolysate was done to mask the intense fishy odor and bitterness of protein hydrolysate

The protein enriched Ready to Cook soup mix was formulated using microencapsulated protein hydrolysates. The developed product contains high amount of protein content and moderate antioxidant activity with acceptable aroma and taste. The developed products also help both high- & low-income populations to fight against malnutrition.

List of publications

Kumari, A., Kaushik, N., & Slizyte, R. (2022). Production and Microencapsulation of Protein Hydrolysate of Pink Perch (Nemipterus japonicus) By-Products Obtained from Surimi Industry for Its Sustainable Utilization. Waste and Biomass Valorization, 1-18. https://doi.org/10.1007/s12649-022-01853-3